What Kind of Products are Resistors and Resistors?

I. Introduction

Resistors are fundamental components in electronic circuits, playing a crucial role in controlling the flow of electric current. They are designed to provide a specific amount of resistance, which is essential for the proper functioning of various electronic devices. In this blog post, we will explore the different types of resistors, their applications across various industries, how to select the right resistor for your needs, the manufacturing processes involved, and the future trends in resistor technology.

II. Understanding Resistors

A. Basic Functionality

At the heart of a resistor's functionality is Ohm's Law, which states that the current (I) flowing through a conductor between two points is directly proportional to the voltage (V) across the two points and inversely proportional to the resistance (R) of the conductor. This relationship can be expressed with the formula:

\[ I = \frac{V}{R} \]

Resistors are primarily used to limit current, divide voltages, and protect sensitive components from excessive current. By controlling the flow of electricity, resistors help ensure that electronic devices operate safely and efficiently.

B. Types of Resistors

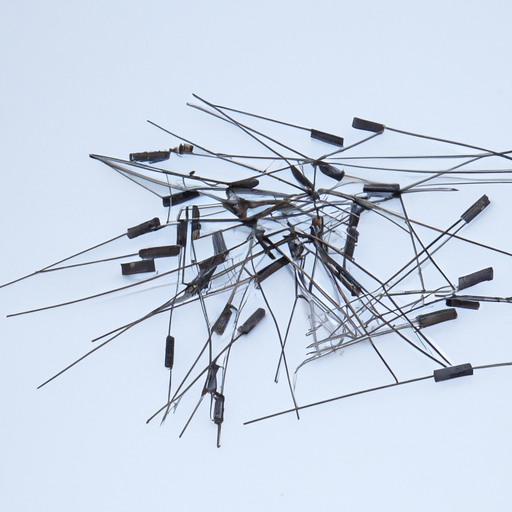

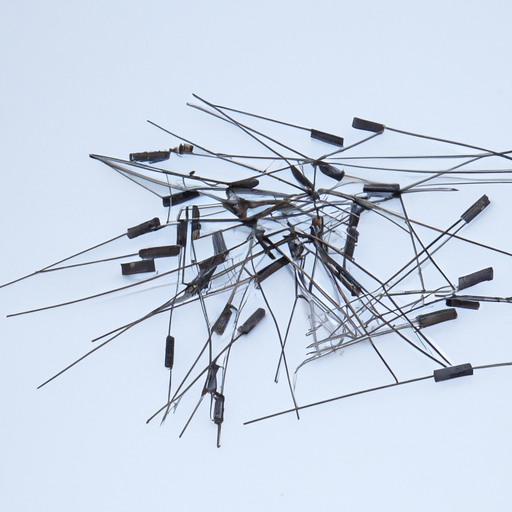

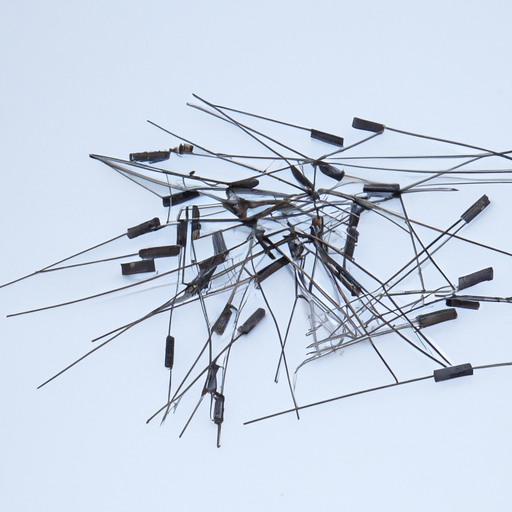

Resistors come in various types, each designed for specific applications and functionalities.

1. Fixed Resistors

Fixed resistors have a constant resistance value and are the most commonly used type. They can be further categorized into:

Carbon Composition Resistors: Made from a mixture of carbon and a binding material, these resistors are known for their high energy absorption and ability to withstand high temperatures. However, they have a higher tolerance and are less stable than other types.

Metal Film Resistors: These resistors are made by depositing a thin layer of metal onto a ceramic substrate. They offer better stability and lower noise levels compared to carbon composition resistors, making them ideal for precision applications.

Wirewound Resistors: Constructed by winding a metal wire around a ceramic or fiberglass core, wirewound resistors can handle high power levels and are often used in applications requiring high precision.

2. Variable Resistors

Variable resistors allow users to adjust the resistance value according to their needs. They include:

Potentiometers: These are commonly used in volume controls and other applications where variable resistance is required. They consist of a resistive element and a movable contact.

Rheostats: Similar to potentiometers but designed to handle higher currents, rheostats are often used in applications like dimmer switches and motor speed controls.

3. Specialty Resistors

Specialty resistors are designed for specific applications and include:

Thermistors: Temperature-sensitive resistors that change resistance with temperature variations. They are widely used in temperature sensing and control applications.

Photoresistors: Also known as light-dependent resistors (LDRs), these resistors change their resistance based on the amount of light they are exposed to. They are commonly used in light-sensing applications.

Varistors: Voltage-dependent resistors that change resistance with voltage fluctuations. They are often used for surge protection in electronic circuits.

III. Applications of Resistors

Resistors are ubiquitous in various industries, serving critical functions in numerous applications.

A. In Consumer Electronics

In consumer electronics, resistors are found in devices such as audio equipment and home appliances. They help control volume levels, manage power distribution, and protect sensitive components from damage.

B. In Industrial Applications

In industrial settings, resistors play a vital role in automation systems and power distribution. They are used in control circuits, motor drives, and other applications where precise current regulation is necessary.

C. In Automotive Electronics

Automotive electronics rely heavily on resistors for various functions, including engine control units and safety systems. Resistors help manage sensor signals, control lighting systems, and ensure the proper functioning of electronic control units.

D. In Telecommunications

In telecommunications, resistors are essential for signal processing and network equipment. They help maintain signal integrity, manage power levels, and protect sensitive components from voltage spikes.

IV. Selecting the Right Resistor

Choosing the right resistor for a specific application involves considering several key specifications.

A. Key Specifications

1. **Resistance Value**: The resistance value, measured in ohms, is the primary specification to consider. It should match the requirements of the circuit.

2. **Power Rating**: The power rating indicates the maximum power the resistor can handle without overheating. It is crucial to select a resistor with an appropriate power rating for the application.

3. **Tolerance**: Tolerance refers to the allowable deviation from the specified resistance value. A lower tolerance indicates higher precision.

B. Environmental Considerations

1. **Temperature Coefficient**: This specification indicates how much the resistance value changes with temperature. It is essential for applications where temperature fluctuations are expected.

2. **Moisture Resistance**: In environments with high humidity or exposure to moisture, selecting resistors with moisture-resistant properties is vital to ensure reliability.

C. Application-Specific Requirements

1. **Size and Form Factor**: The physical size and shape of the resistor may be critical, especially in compact electronic devices.

2. **Reliability and Lifespan**: Consideration of the expected lifespan and reliability of the resistor is essential, particularly in mission-critical applications.

V. Manufacturing and Quality Control

The manufacturing process of resistors involves several steps to ensure quality and performance.

A. Production Processes

1. **Material Selection**: The choice of materials significantly impacts the performance and reliability of resistors. High-quality materials are essential for producing durable and stable resistors.

2. **Fabrication Techniques**: Various fabrication techniques, such as thin-film and thick-film processes, are used to create resistors with specific characteristics.

B. Quality Assurance

1. **Testing Methods**: Rigorous testing methods are employed to ensure that resistors meet specified performance criteria. This includes testing for resistance value, power rating, and tolerance.

2. **Standards and Certifications**: Compliance with industry standards and certifications is crucial for ensuring the quality and reliability of resistors.

VI. Future Trends in Resistor Technology

As technology continues to evolve, so do resistors. Here are some future trends to watch for in resistor technology.

A. Innovations in Materials

1. **Carbon Nanotubes**: Research into carbon nanotube-based resistors is ongoing, as these materials offer unique properties that could lead to more efficient and compact resistors.

2. **Flexible Resistors**: The development of flexible resistors is paving the way for new applications in wearable technology and flexible electronics.

B. Smart Resistors

1. **Integration with IoT**: The rise of the Internet of Things (IoT) is driving the development of smart resistors that can communicate and adapt to changing conditions in real-time.

2. **Adaptive Resistance**: Future resistors may feature adaptive resistance capabilities, allowing them to adjust their resistance based on environmental factors or circuit demands.

C. Sustainability in Resistor Production

1. **Eco-friendly Materials**: The push for sustainability is leading to the exploration of eco-friendly materials in resistor production, reducing the environmental impact of manufacturing processes.

2. **Recycling Initiatives**: Efforts to recycle and repurpose electronic components, including resistors, are gaining traction, promoting a circular economy in the electronics industry.

VII. Conclusion

Resistors are indispensable components in electronic circuits, serving a wide range of functions across various industries. Understanding the different types of resistors, their applications, and how to select the right one is essential for anyone working with electronics. As technology continues to advance, resistors will evolve, incorporating new materials and smart features that enhance their functionality and sustainability. The future of resistor technology promises exciting developments that will further integrate these components into the ever-evolving landscape of electronics.

VIII. References

- Academic Journals

- Industry Publications

- Online Resources and Databases

In conclusion, resistors are more than just passive components; they are vital to the functionality and reliability of electronic devices. As we look to the future, the ongoing innovations in resistor technology will undoubtedly shape the next generation of electronic applications.

What Kind of Products are Resistors and Resistors?

I. Introduction

Resistors are fundamental components in electronic circuits, playing a crucial role in controlling the flow of electric current. They are designed to provide a specific amount of resistance, which is essential for the proper functioning of various electronic devices. In this blog post, we will explore the different types of resistors, their applications across various industries, how to select the right resistor for your needs, the manufacturing processes involved, and the future trends in resistor technology.

II. Understanding Resistors

A. Basic Functionality

At the heart of a resistor's functionality is Ohm's Law, which states that the current (I) flowing through a conductor between two points is directly proportional to the voltage (V) across the two points and inversely proportional to the resistance (R) of the conductor. This relationship can be expressed with the formula:

\[ I = \frac{V}{R} \]

Resistors are primarily used to limit current, divide voltages, and protect sensitive components from excessive current. By controlling the flow of electricity, resistors help ensure that electronic devices operate safely and efficiently.

B. Types of Resistors

Resistors come in various types, each designed for specific applications and functionalities.

1. Fixed Resistors

Fixed resistors have a constant resistance value and are the most commonly used type. They can be further categorized into:

Carbon Composition Resistors: Made from a mixture of carbon and a binding material, these resistors are known for their high energy absorption and ability to withstand high temperatures. However, they have a higher tolerance and are less stable than other types.

Metal Film Resistors: These resistors are made by depositing a thin layer of metal onto a ceramic substrate. They offer better stability and lower noise levels compared to carbon composition resistors, making them ideal for precision applications.

Wirewound Resistors: Constructed by winding a metal wire around a ceramic or fiberglass core, wirewound resistors can handle high power levels and are often used in applications requiring high precision.

2. Variable Resistors

Variable resistors allow users to adjust the resistance value according to their needs. They include:

Potentiometers: These are commonly used in volume controls and other applications where variable resistance is required. They consist of a resistive element and a movable contact.

Rheostats: Similar to potentiometers but designed to handle higher currents, rheostats are often used in applications like dimmer switches and motor speed controls.

3. Specialty Resistors

Specialty resistors are designed for specific applications and include:

Thermistors: Temperature-sensitive resistors that change resistance with temperature variations. They are widely used in temperature sensing and control applications.

Photoresistors: Also known as light-dependent resistors (LDRs), these resistors change their resistance based on the amount of light they are exposed to. They are commonly used in light-sensing applications.

Varistors: Voltage-dependent resistors that change resistance with voltage fluctuations. They are often used for surge protection in electronic circuits.

III. Applications of Resistors

Resistors are ubiquitous in various industries, serving critical functions in numerous applications.

A. In Consumer Electronics

In consumer electronics, resistors are found in devices such as audio equipment and home appliances. They help control volume levels, manage power distribution, and protect sensitive components from damage.

B. In Industrial Applications

In industrial settings, resistors play a vital role in automation systems and power distribution. They are used in control circuits, motor drives, and other applications where precise current regulation is necessary.

C. In Automotive Electronics

Automotive electronics rely heavily on resistors for various functions, including engine control units and safety systems. Resistors help manage sensor signals, control lighting systems, and ensure the proper functioning of electronic control units.

D. In Telecommunications

In telecommunications, resistors are essential for signal processing and network equipment. They help maintain signal integrity, manage power levels, and protect sensitive components from voltage spikes.

IV. Selecting the Right Resistor

Choosing the right resistor for a specific application involves considering several key specifications.

A. Key Specifications

1. **Resistance Value**: The resistance value, measured in ohms, is the primary specification to consider. It should match the requirements of the circuit.

2. **Power Rating**: The power rating indicates the maximum power the resistor can handle without overheating. It is crucial to select a resistor with an appropriate power rating for the application.

3. **Tolerance**: Tolerance refers to the allowable deviation from the specified resistance value. A lower tolerance indicates higher precision.

B. Environmental Considerations

1. **Temperature Coefficient**: This specification indicates how much the resistance value changes with temperature. It is essential for applications where temperature fluctuations are expected.

2. **Moisture Resistance**: In environments with high humidity or exposure to moisture, selecting resistors with moisture-resistant properties is vital to ensure reliability.

C. Application-Specific Requirements

1. **Size and Form Factor**: The physical size and shape of the resistor may be critical, especially in compact electronic devices.

2. **Reliability and Lifespan**: Consideration of the expected lifespan and reliability of the resistor is essential, particularly in mission-critical applications.

V. Manufacturing and Quality Control

The manufacturing process of resistors involves several steps to ensure quality and performance.

A. Production Processes

1. **Material Selection**: The choice of materials significantly impacts the performance and reliability of resistors. High-quality materials are essential for producing durable and stable resistors.

2. **Fabrication Techniques**: Various fabrication techniques, such as thin-film and thick-film processes, are used to create resistors with specific characteristics.

B. Quality Assurance

1. **Testing Methods**: Rigorous testing methods are employed to ensure that resistors meet specified performance criteria. This includes testing for resistance value, power rating, and tolerance.

2. **Standards and Certifications**: Compliance with industry standards and certifications is crucial for ensuring the quality and reliability of resistors.

VI. Future Trends in Resistor Technology

As technology continues to evolve, so do resistors. Here are some future trends to watch for in resistor technology.

A. Innovations in Materials

1. **Carbon Nanotubes**: Research into carbon nanotube-based resistors is ongoing, as these materials offer unique properties that could lead to more efficient and compact resistors.

2. **Flexible Resistors**: The development of flexible resistors is paving the way for new applications in wearable technology and flexible electronics.

B. Smart Resistors

1. **Integration with IoT**: The rise of the Internet of Things (IoT) is driving the development of smart resistors that can communicate and adapt to changing conditions in real-time.

2. **Adaptive Resistance**: Future resistors may feature adaptive resistance capabilities, allowing them to adjust their resistance based on environmental factors or circuit demands.

C. Sustainability in Resistor Production

1. **Eco-friendly Materials**: The push for sustainability is leading to the exploration of eco-friendly materials in resistor production, reducing the environmental impact of manufacturing processes.

2. **Recycling Initiatives**: Efforts to recycle and repurpose electronic components, including resistors, are gaining traction, promoting a circular economy in the electronics industry.

VII. Conclusion

Resistors are indispensable components in electronic circuits, serving a wide range of functions across various industries. Understanding the different types of resistors, their applications, and how to select the right one is essential for anyone working with electronics. As technology continues to advance, resistors will evolve, incorporating new materials and smart features that enhance their functionality and sustainability. The future of resistor technology promises exciting developments that will further integrate these components into the ever-evolving landscape of electronics.

VIII. References

- Academic Journals

- Industry Publications

- Online Resources and Databases

In conclusion, resistors are more than just passive components; they are vital to the functionality and reliability of electronic devices. As we look to the future, the ongoing innovations in resistor technology will undoubtedly shape the next generation of electronic applications.