The Latest Power Inductor Specifications

I. Introduction

In the realm of modern electronics, power inductors play a pivotal role in ensuring efficient energy management and signal integrity. These passive components are essential in various applications, from power supply circuits to automotive systems. This blog post aims to provide a comprehensive overview of the latest power inductor specifications, exploring their fundamental principles, key specifications, recent technological advancements, and future trends.

II. Understanding Power Inductors

A. Basic Principles of Inductance

Inductance is a fundamental property of electrical circuits, defined as the ability of a conductor to store energy in a magnetic field when an electric current flows through it. The relationship between current and magnetic field is crucial; as the current increases, the magnetic field strengthens, and vice versa. This principle is the foundation of how inductors function.

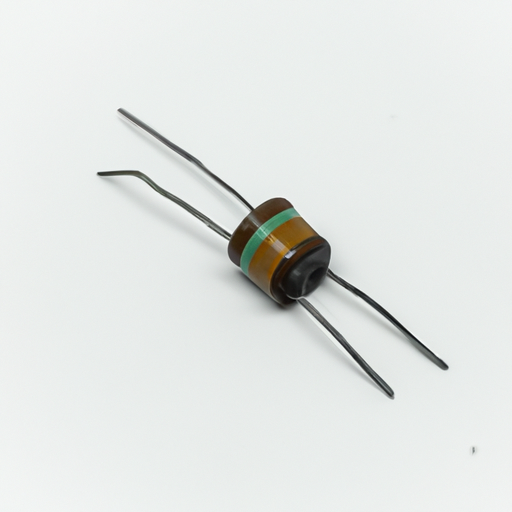

B. Types of Power Inductors

Power inductors come in various types, each suited for specific applications:

1. **Air Core Inductors**: These inductors use air as the core material, offering low inductance values and high-frequency performance. They are often used in RF applications.

2. **Ferrite Core Inductors**: Ferrite cores provide higher inductance values and are commonly used in power supply circuits due to their efficiency in magnetic field containment.

3. **Iron Powder Inductors**: These inductors are made from iron powder and are known for their high saturation current capabilities, making them suitable for high-power applications.

4. **Composite Inductors**: Combining different materials, composite inductors offer a balance between performance and size, making them versatile for various applications.

III. Key Specifications of Power Inductors

Understanding the specifications of power inductors is crucial for selecting the right component for a given application. Here are the key specifications to consider:

A. Inductance Value

Inductance is measured in henries (H) and is a critical parameter in circuit design. The inductance value determines how much energy the inductor can store and release, influencing the overall performance of the circuit.

B. Current Rating

The current rating indicates the maximum current the inductor can handle without overheating or failing. It is essential to choose an inductor with a current rating that exceeds the expected load to ensure reliability and performance.

C. DC Resistance (DCR)

DC resistance is the resistance of the inductor when a direct current flows through it. Lower DCR values lead to higher efficiency and reduced heat generation, which is vital in high-power applications.

D. Saturation Current

Saturation current is the maximum current an inductor can handle before its inductance value begins to drop significantly. Exceeding this level can lead to performance degradation and potential circuit failure.

E. Temperature Coefficient

The temperature coefficient indicates how the inductance value changes with temperature variations. Understanding this specification is crucial for applications that experience fluctuating environmental conditions.

IV. Recent Advances in Power Inductor Technology

The field of power inductors has seen significant advancements in recent years, driven by the demand for higher efficiency and miniaturization.

A. Materials Innovation

Innovative materials are at the forefront of power inductor development. New core materials, such as high-permeability ferrites and composite materials, enhance performance while reducing size. Additionally, advancements in conductive materials improve efficiency and reduce losses.

B. Miniaturization Trends

As electronic devices become smaller and more compact, the trend toward miniaturization in power inductors has gained momentum. Smaller inductors offer benefits such as reduced weight and space requirements, but they also present challenges in terms of heat management and performance.

C. Enhanced Thermal Management

Effective thermal management is crucial in high-power applications. Recent advancements include the development of inductors with improved heat dissipation techniques, such as enhanced surface area and thermal interface materials, ensuring reliable operation under demanding conditions.

V. Applications of Power Inductors

Power inductors find applications across various industries, each with unique requirements.

A. Power Supply Circuits

In power supply circuits, inductors play a vital role in buck and boost converters, helping regulate voltage and current. Their ability to store and release energy efficiently is essential for maintaining stable power output.

B. Automotive Applications

The automotive industry increasingly relies on power inductors, particularly in electric vehicles (EVs) and advanced driver-assistance systems (ADAS). Inductors are used in power management systems, ensuring efficient energy distribution and enhancing vehicle performance.

C. Consumer Electronics

In consumer electronics, power inductors are integral to devices such as smartphones, tablets, and wearables. They help manage power efficiently, contributing to longer battery life and improved device performance.

D. Industrial Applications

In industrial settings, power inductors are used in robotics and automation systems, playing a crucial role in power management and control. Their reliability and efficiency are essential for maintaining operational integrity in demanding environments.

VI. Selecting the Right Power Inductor

Choosing the right power inductor involves careful consideration of several factors.

A. Factors to Consider

1. **Application Requirements**: Understand the specific needs of your application, including current ratings, inductance values, and thermal management requirements.

2. **Environmental Conditions**: Consider the operating environment, including temperature fluctuations and potential exposure to contaminants.

B. Tools and Resources for Selection

Utilize manufacturer specifications and simulation software to evaluate different inductors. These resources can help you make informed decisions based on performance parameters and application needs.

C. Common Mistakes to Avoid

1. **Underestimating Current Ratings**: Always select an inductor with a current rating that exceeds your application's requirements to avoid overheating and failure.

2. **Ignoring Thermal Management Needs**: Ensure that your chosen inductor can effectively dissipate heat, especially in high-power applications.

VII. Future Trends in Power Inductor Design

The future of power inductor design is shaped by several emerging trends.

A. Integration with Other Components

The trend toward hybrid solutions and system-on-chip (SoC) designs is gaining traction. Integrating inductors with other components can lead to more compact and efficient designs, reducing overall system size and complexity.

B. Sustainability and Eco-Friendly Materials

As the electronics industry moves toward sustainability, there is a growing emphasis on eco-friendly materials. This trend impacts material selection and manufacturing processes, promoting greener electronics.

C. The Role of AI and Machine Learning

Artificial intelligence and machine learning are beginning to play a role in the design and testing of power inductors. Predictive design and optimization techniques can enhance performance parameters and streamline the development process.

VIII. Conclusion

In conclusion, power inductors are essential components in modern electronics, with specifications that significantly impact performance and reliability. Understanding the latest specifications, advancements, and trends is crucial for engineers and designers in selecting the right inductors for their applications. As technology continues to evolve, staying updated with the latest developments in power inductor technology will be vital for ensuring efficient and effective electronic designs.

IX. References

1. Academic Journals

2. Industry Reports

3. Manufacturer Data Sheets

This blog post provides a comprehensive overview of the latest power inductor specifications, highlighting their importance in various applications and the ongoing advancements in technology. By understanding these components, engineers can make informed decisions that enhance the performance and reliability of their electronic designs.

The Latest Power Inductor Specifications

I. Introduction

In the realm of modern electronics, power inductors play a pivotal role in ensuring efficient energy management and signal integrity. These passive components are essential in various applications, from power supply circuits to automotive systems. This blog post aims to provide a comprehensive overview of the latest power inductor specifications, exploring their fundamental principles, key specifications, recent technological advancements, and future trends.

II. Understanding Power Inductors

A. Basic Principles of Inductance

Inductance is a fundamental property of electrical circuits, defined as the ability of a conductor to store energy in a magnetic field when an electric current flows through it. The relationship between current and magnetic field is crucial; as the current increases, the magnetic field strengthens, and vice versa. This principle is the foundation of how inductors function.

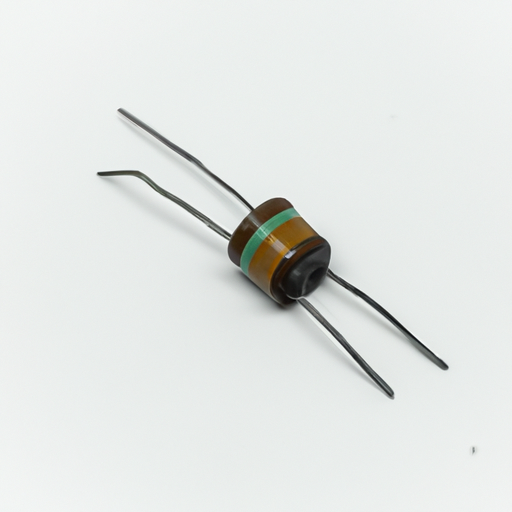

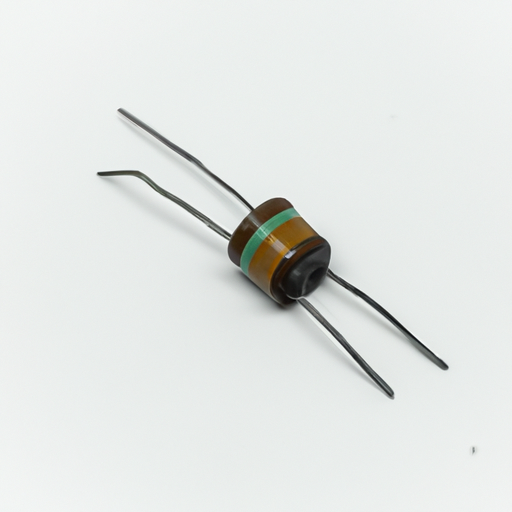

B. Types of Power Inductors

Power inductors come in various types, each suited for specific applications:

1. **Air Core Inductors**: These inductors use air as the core material, offering low inductance values and high-frequency performance. They are often used in RF applications.

2. **Ferrite Core Inductors**: Ferrite cores provide higher inductance values and are commonly used in power supply circuits due to their efficiency in magnetic field containment.

3. **Iron Powder Inductors**: These inductors are made from iron powder and are known for their high saturation current capabilities, making them suitable for high-power applications.

4. **Composite Inductors**: Combining different materials, composite inductors offer a balance between performance and size, making them versatile for various applications.

III. Key Specifications of Power Inductors

Understanding the specifications of power inductors is crucial for selecting the right component for a given application. Here are the key specifications to consider:

A. Inductance Value

Inductance is measured in henries (H) and is a critical parameter in circuit design. The inductance value determines how much energy the inductor can store and release, influencing the overall performance of the circuit.

B. Current Rating

The current rating indicates the maximum current the inductor can handle without overheating or failing. It is essential to choose an inductor with a current rating that exceeds the expected load to ensure reliability and performance.

C. DC Resistance (DCR)

DC resistance is the resistance of the inductor when a direct current flows through it. Lower DCR values lead to higher efficiency and reduced heat generation, which is vital in high-power applications.

D. Saturation Current

Saturation current is the maximum current an inductor can handle before its inductance value begins to drop significantly. Exceeding this level can lead to performance degradation and potential circuit failure.

E. Temperature Coefficient

The temperature coefficient indicates how the inductance value changes with temperature variations. Understanding this specification is crucial for applications that experience fluctuating environmental conditions.

IV. Recent Advances in Power Inductor Technology

The field of power inductors has seen significant advancements in recent years, driven by the demand for higher efficiency and miniaturization.

A. Materials Innovation

Innovative materials are at the forefront of power inductor development. New core materials, such as high-permeability ferrites and composite materials, enhance performance while reducing size. Additionally, advancements in conductive materials improve efficiency and reduce losses.

B. Miniaturization Trends

As electronic devices become smaller and more compact, the trend toward miniaturization in power inductors has gained momentum. Smaller inductors offer benefits such as reduced weight and space requirements, but they also present challenges in terms of heat management and performance.

C. Enhanced Thermal Management

Effective thermal management is crucial in high-power applications. Recent advancements include the development of inductors with improved heat dissipation techniques, such as enhanced surface area and thermal interface materials, ensuring reliable operation under demanding conditions.

V. Applications of Power Inductors

Power inductors find applications across various industries, each with unique requirements.

A. Power Supply Circuits

In power supply circuits, inductors play a vital role in buck and boost converters, helping regulate voltage and current. Their ability to store and release energy efficiently is essential for maintaining stable power output.

B. Automotive Applications

The automotive industry increasingly relies on power inductors, particularly in electric vehicles (EVs) and advanced driver-assistance systems (ADAS). Inductors are used in power management systems, ensuring efficient energy distribution and enhancing vehicle performance.

C. Consumer Electronics

In consumer electronics, power inductors are integral to devices such as smartphones, tablets, and wearables. They help manage power efficiently, contributing to longer battery life and improved device performance.

D. Industrial Applications

In industrial settings, power inductors are used in robotics and automation systems, playing a crucial role in power management and control. Their reliability and efficiency are essential for maintaining operational integrity in demanding environments.

VI. Selecting the Right Power Inductor

Choosing the right power inductor involves careful consideration of several factors.

A. Factors to Consider

1. **Application Requirements**: Understand the specific needs of your application, including current ratings, inductance values, and thermal management requirements.

2. **Environmental Conditions**: Consider the operating environment, including temperature fluctuations and potential exposure to contaminants.

B. Tools and Resources for Selection

Utilize manufacturer specifications and simulation software to evaluate different inductors. These resources can help you make informed decisions based on performance parameters and application needs.

C. Common Mistakes to Avoid

1. **Underestimating Current Ratings**: Always select an inductor with a current rating that exceeds your application's requirements to avoid overheating and failure.

2. **Ignoring Thermal Management Needs**: Ensure that your chosen inductor can effectively dissipate heat, especially in high-power applications.

VII. Future Trends in Power Inductor Design

The future of power inductor design is shaped by several emerging trends.

A. Integration with Other Components

The trend toward hybrid solutions and system-on-chip (SoC) designs is gaining traction. Integrating inductors with other components can lead to more compact and efficient designs, reducing overall system size and complexity.

B. Sustainability and Eco-Friendly Materials

As the electronics industry moves toward sustainability, there is a growing emphasis on eco-friendly materials. This trend impacts material selection and manufacturing processes, promoting greener electronics.

C. The Role of AI and Machine Learning

Artificial intelligence and machine learning are beginning to play a role in the design and testing of power inductors. Predictive design and optimization techniques can enhance performance parameters and streamline the development process.

VIII. Conclusion

In conclusion, power inductors are essential components in modern electronics, with specifications that significantly impact performance and reliability. Understanding the latest specifications, advancements, and trends is crucial for engineers and designers in selecting the right inductors for their applications. As technology continues to evolve, staying updated with the latest developments in power inductor technology will be vital for ensuring efficient and effective electronic designs.

IX. References

1. Academic Journals

2. Industry Reports

3. Manufacturer Data Sheets

This blog post provides a comprehensive overview of the latest power inductor specifications, highlighting their importance in various applications and the ongoing advancements in technology. By understanding these components, engineers can make informed decisions that enhance the performance and reliability of their electronic designs.